Product Name: Brass 1/2'' Motorized Valve, 3-Way Electric Shut-off Valve, 1.0Mpa, On/Off 5sec, 2/3/5 Wires.TF15-B3-A.

Technical Parameters:

| Product | 3 Way Motorized Ball Valve / Electric Shut-off Valve / Automated Valve |

| Model | TF15-B3-A |

| Valve Size | 1/2'', DN15 (3 way T type) |

| Valve Material | Brass |

| Working Voltage | DC5V, DC12V DC24V, AC/DC9-24V, AC110-230V (Optional) |

| Valve On/Off Time: | 5 Sec to open; 5 sec to closed |

| Wiring Control Method | CR201, CR202, CR301, CR303, CR401, CR501, CR502 (Optional) |

| Working Current: | ≤80MA (500 mA shown on the lable means the minimum current of external power) |

| Max Working Pressure | 1.0Mpa (10bar, 135 psi) |

| Valve Thread | BSP (for Europe, Asia,Oceania and Africa market) NPT (for America, Canada and Mexico market) |

| Flow Mediam | Water, Air |

| Environment temperature: | -15℃ ~ 50℃ |

| Liquid temperature: | 2℃ ~ 95℃ |

| Sealing material: | EPDM & PTFE |

| Actuator material: | Engineering plastics |

| Actuator rotation: | 90 degree |

| Max. torque force: | 2 Nm |

| Cable length: | 0.5m |

| Life time: | 100,000 times |

| Protection class: | IP67 |

| Certification | CE, IP67 |

| Manual override: | No |

Question 1: How to identify the model of TF Automated Valve?

For Example: TF15-B3 -A.

TF=Our Company Name;

15=Valve Size, DN15=1/2'', DN20=3/4'', DN25=1'' etc.

B =Brass; S =Stainless Steel;

3 =3 way valve; (2=2 way valve);

A= On/off valve (we have A/B/C series valve for selection)

Question 2: What is TF motorized valve's advantage compare to other valves?

1) Float sealing struction,No Leak,can be suitable for various water treatment,even high-fouling area.

2) Integrated design of valve body and electic actuator,small size and light weight,very suitable for small equipment.

3) Can replace the solenoid valve in the conditions that the solenoid valve can not be worked.

4) Valve bore full port design, do not lose any flow.

5) Long serving life,approx 100,000 open/close times

6) High reliable working performance & price ratio,you have NOT worries at afterservice and reselling.

7) Low current ≤80MA (500 mA shown on the lable means the minimum current of external power), suitable for battery driving.

8) Open/close time approx 3~5 seconds,fast response&action.

9) Actuators are sealed to IP67 specifications to prevent water ingress,ideal for indoor or outdoor installation.

Question 3: How do I order valves from TF?

The following factors is important when you ask for the valve price from us:

1. Your Pipe Size = Our Valve Size

2. Your Wokr Voltage: DC Power: DC5V, DC12V, DC24V? AC Power: AC12V, AC24V or AC110V-230V

3. Valve Material: Brass Valve or Stainless Steel Valve ?

4. Control Metod: After the voltage confirmed, we can guide you to find suitable control method from our wiring diagrams. Usually, the wires option should be same as your controller or equipment design.

Question 4: How about the quality control of TF brand motorized ball valve?

1, Actuator housing use high quality engineering plastic for prevent aging and UV;

2, Metal gear system can guarantee the valve operation steady and long life working;

3, 200 times electronic performance testing before sending out, each valve should open/closed 200 times by power in this testing;

4, Type ID number to each batch valves;

5, The protection class is also IP67, all actuators are fully sealed to IP67 specifications to prevent water ingress;

6, Floating seal structure, no leak, suitable for heavy dirt or long time working. No leaking, high protection class, NEMA 6 equivalent;

7, Most of other supplier offer reduce port only. TF series motorized valve features a full port ball valve, the valve do not lose any water flow or pressure on the working.

8, Offer NPT thread valve for America and Canada market, and offer BSP thread valve for other country.

9, Different wiring control methods for option which include 2/3/5 wires control, normal open/closed, signal feedback etc.

10. Acquired CE certification and ISO certification.

Most of our old clients used TF brand motorized valve for water applications as bellow:

1. Automated Leak Detection & Water Shut-off System

2. Water heater&boiler system

3. Centre heating system

4. Water treatment, water reclying, water purification

5. Electric Brewing system

6. Smart water meters, solar water systems.

7. Drinking water equipment, washing machine

8. Chemical process, water softener

9. HVAC, central air conditioning, fan coil

10. Water saving irrigation, automatic control system, industrial mini automatic control equipment.

Electric Valve Dimension:

Main components material:

No. | Name | Material | Qty |

1 | Actuator | PPO | 1 |

2 | Body cover | Brass | 1 |

3 | O-ring | FKM | 4 |

4 | Sealing | PTFE | 4 |

5 | Ball | SS304 | 1 |

6 | Steam | Brass | 1 |

7 | O-ring | FKM | 2 |

Electric Valve Dimension:

Size (mm) | D1/D2 | d1 | L1 | L2/L3 | E1 | H1 | H2 |

TF8(1/4”) Electric valve | 1/4” | 6 | 51 | 11 | 20.2 | 78.5 | 11 |

TF10(3/8”) Electric valve | 3/8” | 6 | 51 | 11 | 20.2 | 78.5 | 11 |

TF15(1/2”) Electric valve | 1/2” | 12 | 70 | 16 | 27 | 84.5 | 17 |

TF20(3/4”) Electric valve | 3/4” | 15 | 75 | 16 | 31 | 89 | 20.5 |

TF25(1”) Electric valve | 1” | 18 | 85 | 17 | 38 | 90.5 | 22.5 |

Wiring Diagram:

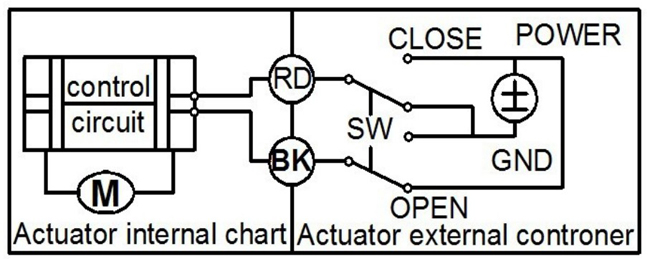

CR2 01 Wiring Diagram (2 wires control, polarity reverse control)

1.RD connect with positive, the BK connect with negative, the valve closed, the actuator automatically

power off after in place , the valve remains fully closed position.

2. BK connect with positive, the RD connect with negative, the valve open, the actuator automatically

power off after in place, the valve remains fully open position.

﹡Suitable Working Voltage: DC5V/DC12V/DC24V.

﹡Exceeding the working voltage is forbidden.

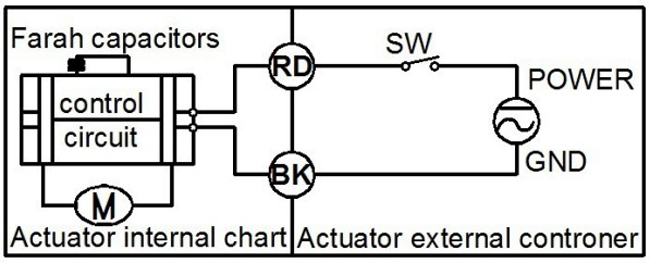

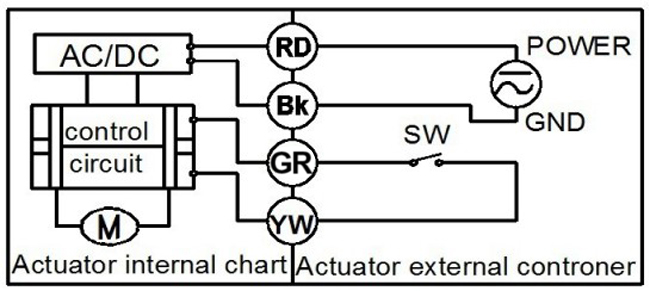

CR2 02 Wiring Diagram (2 wires control – auto return if power failure)

1.When SW is closed , the valve open. the actuator automatically power off after in place.

2.When SW is open, the valve closed, the actuator automatically power off after in place.

﹡ Suitable Working Voltage: AC/DC9-24V ,AC110V-230V, AC/DC9-35V(with manual override).

﹡Exceeding the working voltage is forbidden.

﹡First Charging time should be 60 seconds at least.

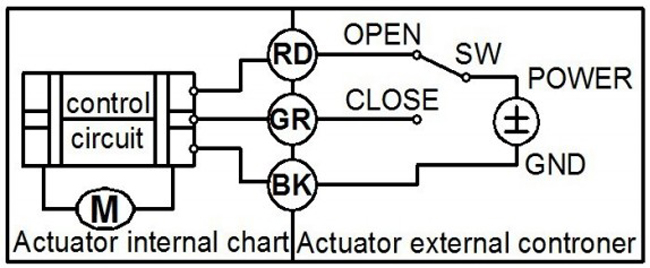

CR3 01 Wiring Diagram (3 wires control)

1.RD & GR connect with positive, BK connect with negative.

2.When OPEN( RD) & SW connected , the valve open, the actuator automatically power off after in

place, valve remains fully open position.

3.When CLOSE(GR) & SW connected, the valve closed, the actuator automatically power off after in

place, valve remains fully closed position.

﹡Suitable Working Voltage: DC5V/DC12V/DC24V, AC/DC9-35V.

﹡Exceeding the working voltage is forbidden.

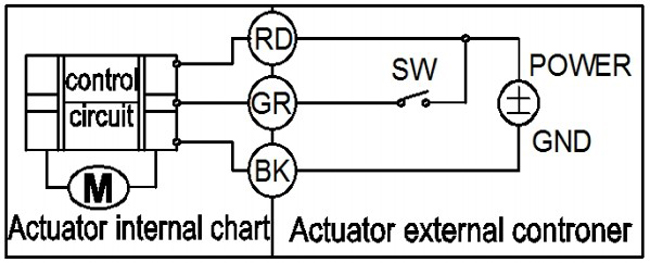

CR3 03 Wiring Diagram (3 wires control)

1. RD& GR connect with positive, the BK connect with negative。

2.SW CLOSED, the valve OPEN, the actuator automatically power off after in place

3.SW OPEN, the valve CLOSED, the actuator automatically power off after in place.

﹡Suitable Working Voltage: AC/DC9-35V, AC110V-230V

﹡Exceeding the working voltage is forbidden

CR4 01 Wiring Diagram (4 wires control)

1. RD & BK are connected to the power, WT & YW are connected to the controlled wiring.

2. When the SW is closed , the valve open.

3. When the SW is open , the valve closed.

﹡Suitable Working Voltage::AC110V-230V.

﹡Exceeding the working voltage is forbidden.

CR5 01 Wiring diagram (with signal feedback)

1. RD connect with positive, the BK connect with negative, the valve closed, the actuator

automatically power off after in place.

2. BK connect with positive, the RD connect with negative,the valve open, the actuator automatically

power off after in place.

3. BL & WT are connect when the valve open fully , YW & WT are connect when the valve closed fully.

﹡Suitable Working Voltage::DC5V/DC12V/DC24V

﹡Exceeding the working voltage is forbidden

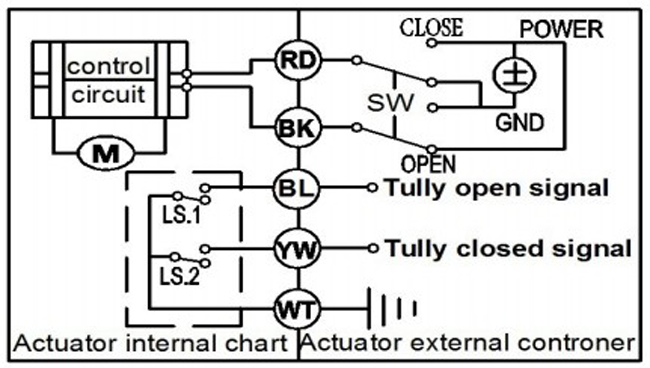

CR5 02 Wiring diagram (with feedback signal)

1. When SW is closed , the valve open. the actuator automatically power off after in place.

2. When SW is open, the valve closed, the actuator automatically power off after in place.

﹡BL & WT are connect when the valve open fully, YW & WT are connect when the valve closed fully.

﹡ Suitable Working Voltage: AC9-24V, AC110V-230V.

﹡Exceeding the working voltage is forbidden.